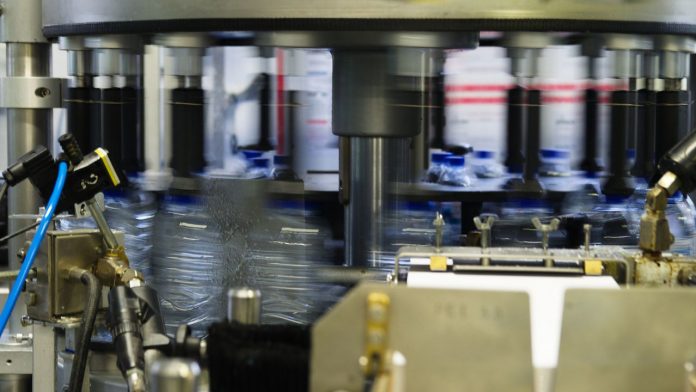

In modern manufacturing and packaging industries, labeling systems play a crucial role in ensuring products are correctly labeled with essential information. However, like any other automated equipment, labeling systems can encounter operational issues or malfunctions.

To address this, many advanced labeling systems are now equipped with automatic fault diagnosis features. This article will explain the importance of automatic fault diagnosis in labeling systems and how it helps improve efficiency and reduce downtime.

What is Automatic Fault Diagnosis?

Automatic fault diagnosis is a technology integrated into labeling systems that can identify, analyze, and sometimes resolve issues without requiring manual intervention.

When a fault occurs, the system immediately detects the problem, identifies the root cause, and provides feedback to operators. In some cases, the system can even correct minor issues on its own, minimizing interruptions in production.

This diagnostic capability is vital for industries where high-volume production is necessary, such as pharmaceuticals, food and beverage, and cosmetics. Quick identification and resolution of faults can prevent costly delays and ensure products are correctly labeled and ready for market.

Common Faults Detected by Labeling Systems

Labeling systems may experience various common faults during operation. Some examples include:

- Label Misalignment: This occurs when the label is not applied in the correct position on the product. An automatic fault diagnosis system can detect when labels are misaligned and signal the machine to stop or correct the error.

- Labeling Speed Issues: A mismatch between the labeling machine speed and conveyor belt speed can cause labels to be applied improperly. Automatic systems can monitor and adjust speed settings to ensure synchronization.

- Label Jams: When labels become stuck in the machine, it can halt production. Automatic fault diagnosis can quickly detect jams and alert operators to fix the issue.

- Print Errors: Printing on labels, such as barcodes or expiration dates, may be missing or smudged. The system can detect such errors and stop the machine to avoid wasting products.

How Does Automatic Fault Diagnosis Improve Efficiency?

Automatic fault diagnosis in labeling systems offers several key benefits that improve operational efficiency:

- Reduced Downtime: By detecting issues in real-time, the system can stop the machine before a small problem escalates. This reduces the need for lengthy manual inspections and repairs.

- Minimized Waste: Labels applied incorrectly or damaged during production can lead to significant waste. Automatic fault detection helps identify faulty processes early, preventing the production of mislabeled products.

- Faster Troubleshooting: Operators are quickly informed of the exact issue through on-screen alerts or automated reports. This reduces the time needed for troubleshooting and allows faster corrective actions.

- Enhanced Productivity: The machine can continue operating with fewer interruptions, allowing for continuous production and higher output rates. With fewer unexpected stops, productivity increases, leading to higher overall efficiency.

Conclusion

The automatic fault diagnosis feature in labeling systems is a valuable tool that helps manufacturers maintain high-quality production while reducing downtime and waste.

By detecting issues such as label misalignment, speed mismatches, jams, and print errors in real-time, these systems enable quick corrective action, ensuring that production processes run smoothly.

As automation continues to advance, automatic fault diagnosis will become an even more integral part of labeling systems, driving efficiency and accuracy across industries.